The top problems your school will face with a legionella risk assessment.

Hi, my name is Holly, and I have been a part of the Dantek team for over 14 years. In the upcoming months, I will be discussing the common problems schools face when it comes to legionella risk assessments, I am going to be talking about the top problems your school will face with legionella risk assessments, being open and honest throughout. Dantek has over 20 years of experience with an excellent, dedicated, and qualified team of field-based technicians, legionella risk assessors, and water treatment specialists.

Your school needs to consider all risks, consequently, you may feel you are drowning in risk assessments which the water risk assessment is just one!

Having two young children in school I can see how hard the staff work. Not just the teachers but everyone, support staff, cleaners, and maintenance. The entire school is based around a profound team who works together to allow pupils to succeed and have a safe space to learn.

I don’t know the first thing about running a school or teaching a class of 30 energetic pupils, but I do know that I want to help you to make one of the tasks on your desk a little easier to understand and manage.

Top problems with a legionella risk assessment!

Top problems with a legionella risk assessment!Being a responsible person in a school is hard work and the pile-up of multiple risk assessments never seems to end. Your number one main priority is to make your school a safe place for your pupils, staff, and visitors. As legionella control specialists we know the frustrations that are felt! Split properties across your campus including sports halls, residential blocks, catering facilities, and frankly any building that has a tap-in it!

Needs must! This has now resulted in a huge document on your desk plus multiple smaller versions you now must read and make sense of. The feeling of being overwhelmed, frustrated, cross, and bored springs to mind.

Top 5 problems with legionella risk assessments!

- April’s Blog: Is your Legionella risk assessment current and when does it need to be updated? How will you know?

- April’s Blog: Written scheme. What is it and how do I write one?

- May’s Blog: How safe can my school ever be?

- May’s Blog: Asset registers. Mind-blowing pages of cold taps, hot taps and mixer valves etc. What’s the point?

- June’s Blog: Remedial actions: Do I have to do all of them and how do I choose the correct contractor?

This month, I am going to try and help you answer questions 1 and 2. If you have a problem or question that is not covered, please email holly@dantek.co.uk

All risk assessments are classed as a “working document” and under current guidelines, a risk assessment must be carried out whenever the Approved code of practice L8 and guidance applies.

What does that mean?

Legionella risk assessment front page! A resurvey date is initially controlled by the attending risk assessor, based on site-specific findings, A simple risk score is then generated. High, medium, and low. Your resurvey date could be in the range of 6 months to 5 years.

That’s not where it ends. Just because you have had a legionella risk assessment completed and the resurvey date clearly states 24 months from now, doesn’t mean that it won’t be required sooner. Simple amendments to the working document may be required, or a brand-new assessment dependent on school changes.

- To put it simply, if your school decides to change the math block, into an additional shower block for the growing sports hall, you will need a new assessment. This is known as “A change to any of the assessed water systems or its use”.

- 3 months have passed and calorifier 1 in the science block has not been achieving 60°C and your outlet temperatures are within the primary growth range. Your control regime is indicating that control is not being achieved. A review is needed.

- A simple staff change. The statutory duty holder was Miss Cox and is now Mrs. Harris. Site responsibility used to be Mr. West, but, he has now retired, and Miss Davies has been appointed. These key personnel changes have now made your assessment enter the “review” stage.

Always remember that the legionella risk assessment is a working document and must be current.

![]() My top tip! Add your legionella risk assessment to your to-do planner, 6 monthly or annually (Dependent on risk) ask yourself these 6 questions.

My top tip! Add your legionella risk assessment to your to-do planner, 6 monthly or annually (Dependent on risk) ask yourself these 6 questions.

- Have any alterations been made to the water systems?

- Has there been changes in the use of the system or the school?

- Has there been any key personnel changes or any that are due to occur?

- Have there been changes to the results of tests indicating that the control measures are no longer effective, or has new information about risks or control measures become available?

- Is my initial risk assessment review date still valid?

- Is the school’s responsible person up to date with training?

In the occurrence of a suspected or confirmed school outbreak or individual case of Legionella associated with the water system, review your risk assessment and written scheme immediately.

You have recently had your legionella risk assessment completed and managed to make headway on the document between your countless emails from parents, maintaining academic success and broadening your school curriculum. Once a quarter you will be sat in front of the school governors and need to advise what are the next steps following your legionella risk assessment. A written scheme!

What is a written scheme? A written scheme of control for the control of legionella is a comprehensive risk management document that clearly identifies the measures required to control the risk of exposure to legionella bacteria, and how those measures are implemented and managed so that control over water systems is achieved and maintained.

Which means… Explain in detail how your school will manage the measures you have implemented to control the risk of legionella and who is responsible.

- Roles & responsibilities i.e. Who has overall responsibility for the safety of all members of the school community? Who manages the day-to-day implementation of the policy? Who is the Responsible person, and statutory site duty holder?

- What are the risks and how will the control tasks be implemented?

- Water hygiene provider contact details if applicable.

- Record keeping.

- Audit of control regime and noncompliance escalation process.

- Schematic drawing.

- Plant shutdown procedures.

- Risk assessment review procedure.

- Emergency procedures in the event of an outbreak or suspected outbreak of Legionella.

In the occurrence of a suspected or confirmed school outbreak or individual case of Legionella associated with the water, review your risk assessment and written scheme immediately.

Management & control flow chart example

- Governing board (If singular school) or Federation governing board (If multiple schools)

- Director

- Chief operations officer

- Director of estates

- Operations Manager

- Maintenance Supervisor

- Estate trade staff

#legionellacontrolinyourschool #legionellacontrol #riskassessment #legionellariskassessment #teamdantek #legionellaadvice #riskassessmentproblems #safeschools #remedialactions #assetregister #riskassessmentupdate #writtenscheme #legionellacontractorsouthwest #legionellacontratorsouthwales #legionellacontractorwestmidlands

Legionella control FAQs

Legionella control FAQs

What is Legionnaires’ Disease?

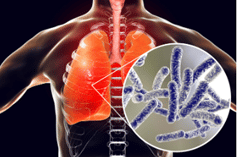

Legionella control FAQs – Legionnaires’ disease is a potentially fatal pneumonia caused by bacteria called Legionella pneumophila. Exposure to the Legionella bacterium can happen when you inhale contaminated mist or breathe in droplets of water contaminated by the bacteria.

There are many ways to prevent legionnaires’ disease, including routine inspection, temperature monitoring, and maintenance of cooling towers, water tanks, and plumbing systems.

Legionella control FAQs

Who can catch Legionnaires’ disease?

Everyone is potentially susceptible to infection, but some people are at a higher risk e.g. those over 45 years of age, smokers and heavy drinkers, those suffering from chronic respiratory or kidney disease, and people whose immune system is impaired. Symptoms of Legionnaires’ disease may include fever, chills, headache, muscle aches, and tiredness.

Everyone is potentially susceptible to infection, but some people are at a higher risk e.g. those over 45 years of age, smokers and heavy drinkers, those suffering from chronic respiratory or kidney disease, and people whose immune system is impaired. Symptoms of Legionnaires’ disease may include fever, chills, headache, muscle aches, and tiredness.

Where is legionella found?

Legionella bacteria (legionella pneumophila) are common in natural water courses such as rivers and ponds. Since legionella is widespread in the environment, they may contaminate and grow in man-made water systems such as cooling towers and hot and cold-water services. Spa baths, Jacuzzi’s and hot tubs also provide a potential breeding ground for legionella bacteria as they provide optimum conditions for the bacteria to grow and multiply to sufficient numbers for a system to be colonised.

Legionella bacteria (legionella pneumophila) are common in natural water courses such as rivers and ponds. Since legionella is widespread in the environment, they may contaminate and grow in man-made water systems such as cooling towers and hot and cold-water services. Spa baths, Jacuzzi’s and hot tubs also provide a potential breeding ground for legionella bacteria as they provide optimum conditions for the bacteria to grow and multiply to sufficient numbers for a system to be colonised.

The bacteria thrives at temperatures between 20 and 45 degrees, particularly if there is a supply of nutrients such as rust, sludge, scale, algae, and other bacteria.

The risk of legionnaires’ disease is increased if water droplets are produced and dispersed in aerosol form for example, in a shower or spa bath.

It is possible to reduce the risk by removing exposure to water droplets and aerosol and by removing the nutrients on which the legionella bacteria feed. This can be done by keeping water systems clean by cleaning and disinfecting cold water storage tanks and showerheads.

How do I the with latest HSE guidance?

The current HSE guidance documents for the legionella control are the L8 Approved Code of Practice and the HSG274 Legionella technical guidance.

The first thing to do is a Legionella Risk Assessment, to consider the risks from legionella that may affect your staff or members of the public, and then take suitable precautions to control and prevent the risk.

Is it a legal requirement to have a legionella risk assessment?

There is a legal duty for employers and landlords to consider the risk legionella bacteria in buildings under your control or management. You must identify and assess the source of risk i.e carry out a legionella risk assessment. Manage the risk. Put in place measures to control or prevent any risks. Keep good records to prove you are taking the appropriate action and to show to external agencies you are following the HSE guidance for legionella control.

What can be used to control legionella bacteria?

Temperature is usually used in hot and cold-water systems, by keeping hot water at above 60 degrees and ensuring it is above 50 degrees at the outlets. Cold water should be kept below 20°c.

There are other methods that can be used if the temperature is not an option, such as copper/silver ionisation and chlorine dioxide. Cooling towers/systems are often treated with biocides. There are other treatment strategies available such as ultraviolet (UV) irradiation.

Do I need to take Legionella samples?

This depends on the risk assessment and control methods being used. In some circumstances it will be required, however, it needs to be done at a UKAS accredited laboratory and will require specialist help. Dantek can provide advice on sample frequency and locations, and what to do if Legionella is detected.

Routine Legionella testing however is not a requirement in domestic hot and cold-water systems. It would only be recommended in hot and cold-water systems due to exceptional circumstances where typical control measures are not working. A full legionella risk assessment would identify the best course of action to reduce the risk.

What will a legionella risk assessment cost?

![]() The cost will depend on what assets are on your site and how many buildings. For large sites or multi-site portfolios a site visit by one of our team is the best way to establish exactly how much a risk assessment will cost. However, we are often able to provide a guide price if you know roughly the size and type of building. For example, how many floors, what it is used for, whether there are any cold-water storage tanks, number of calorifiers and if there are any cooling towers. An asset register of plant and equipment can be very helpful in determining how long the on-site assessment will take and therefore the cost.

The cost will depend on what assets are on your site and how many buildings. For large sites or multi-site portfolios a site visit by one of our team is the best way to establish exactly how much a risk assessment will cost. However, we are often able to provide a guide price if you know roughly the size and type of building. For example, how many floors, what it is used for, whether there are any cold-water storage tanks, number of calorifiers and if there are any cooling towers. An asset register of plant and equipment can be very helpful in determining how long the on-site assessment will take and therefore the cost.

One of our team would be happy to talk through on the phone any requirements and enquiries.

What do Landlords need to do about Legionella control?

The law clearly states if you are a Landlord and rent out your property then you have a duty under Health and Safety Law to consider the risk posed by Legionella bacteria. The ACoP L8 (3rd edition) also states Landlords must assess the risk from exposure to legionella to their tenants.

In most cases the risk assessment is simple and straight forward, however for more complex systems or if the Landlord is not able / competent to carry out the assessment they can use a specialist Water Treatment Company like Dantek, to carry out the legionella risk assessments and advise on any actions required.

A simple risk assessment will identify if a system is considered a low legionella risk and no further actions are required other than to review the assessment regularly in case anything changes which may affect the risk for example the water system in the building changes.

Examples of low risk systems include;

- A small building occupied by people not considered at risk from legionella bacteria.

- Where there is enough usage of water per day to ensure the entire system is changed at least once.

- Mains fed cold water supplies the entire system, so there are no cold-water storage tanks.

- Hot water is fed from combi boilers/ instantaneous heaters or low volume water heater where the hot water is supplied at no less than 50°c

- The only outlets at the property are toilets and wash hand basins with no showers present on site.

http://www.hse.gov.uk/legionnaires/legionella-landlords-responsibilities.htm

What is meant by the term water system?

A water system includes all plant and equipment for example all the pipework, pumps, cold water storage tanks, valves, showers, water softeners, chillers, heat exchangers, cooling towers, calorifiers, little used outlets and dead legs, humidifiers, air washes, car washes, indoor fountains and water features.

How do I choose a water hygiene company?

Choosing a water hygiene company with the knowledge and skills to manage and control the risk of legionnaires’ disease at your site is made easier with the help of the Legionella Control Association. The LCA hold a register of members who have met their requirements on an annual basis and have passed their annual audit of systems.

A key factor should be the training of site staff to carry out water hygiene work competently. A provider will be able to demonstrate how their employees are trained and audited to ensure continual compliance with current standards.

The LCA code of conduct sets out the standard of service a client should expect from a water hygiene provider. The code requires a Service Provider to set up an appropriate management system for the control of legionella complying with the latest HSE guidance for the control of legionella bacteria.

How many cases of Legionnaires Disease were there last year?

The figures from 2021 – 2022 are not available yet however between 1st January – 31st October 2020 according to a report by Public Health England, there were 254 cases of Legionellosis cases reported in England and Wales.

The figures from 2021 – 2022 are not available yet however between 1st January – 31st October 2020 according to a report by Public Health England, there were 254 cases of Legionellosis cases reported in England and Wales.

If you have any questions in regards to Legionella control FAQs or any other questions, please do not hesitate to call us on 01454 417 920

Follow us on

How much should my Legionella risk assessment cost?

Legionella risk assessments: We are all faced with the current climbing inflation across products and services that we require. Compliance can be a huge concern, and we all want the best value without compromising the quality and level of service we receive from our suppliers.

This blog will hopefully shed some light on how to get a fair price for your legionella risk assessment and how you can compare your quotes against each other, allowing you to decide what you are confident with.

As a starting point, visit the legionella control association website, https://www.legionellacontrol.org.uk. All approved LCA Members must provide a range of products and services for the control of legionella bacteria in water systems. They would have also demonstrated that they have complied with the LCA Code of Conduct and LCA Service Standards and are committed to helping their customers prevent legionellosis and keep their water systems safe. The website allows you to search a directory of approved contractors within your area. ![]()

How much will a Legionella risk assessment cost?

A Legionella risk assessment is a consultancy service that will require a physical visit to your site, and follow-on report writing time to produce your document. For your chosen contractor, to provide an accurate quotation for your site, they will first need to establish how long the report will take to complete. Once this is figured out, multiply the time by a day rate, and bingo! A price.

Estimating how long a survey will take is a fine art, but there are some variables

![]() Ask what the standard day rate is for a surveyor, but be careful, some include administration time some don’t. Ask the question.

Ask what the standard day rate is for a surveyor, but be careful, some include administration time some don’t. Ask the question.

Geography?

Where is the site? Or where are the sites? Travel time is working time, and you pay for it. Ideally, you’ll use someone local if you have a big single site or cluster of buildings, but sometimes this isn’t practical. If you have multiple sites, you can get some great reductions from contractors out of your area allowing you to compare multiple quotes. Also, these are fun for the surveyors. Here at Dantek, we assess nationwide contracts including retail, care homes, and even memorial parks. The attending assessors have a great time traveling across the country.

Once you understand the logistics of getting the surveyor to and from the site, how long will they be there? The two big factors in this debate are what water services do you have? And how hard will they look?

Water Assets and system complexity?

I have seen many different approaches to convey what is on-site, varying from line-item asset registers, and copies of the previous risk assessments to lists of the gross internal areas of properties. The surveyor’s point of view generally stems from, how difficult is this system going to be for me to understand and how many assets will I have to survey. For example, a large modern office block could seem like a big beast but may only have a plant room in the basement, a single wet riser by the lift shaft, toilets and kitchenettes on each floor plus a couple of cleaners cupboards, simple. In contrast, a stately home converted to halls of residence can contain multiple systems and a dog’s breakfast of assets and pipework that would reduce the finest to tears.

![]() Legionella risk assessment – Top tip: Give what information you have, including building use, number of storeys, and location

Legionella risk assessment – Top tip: Give what information you have, including building use, number of storeys, and location

The industry refers to all hot and cold-water systems for toilets, sinks, showers etc. as domestic systems. These are almost universally included in risk assessments, but what about cooling towers, industrial uses of water, humidifiers, water features, and medical equipment? The survey should cover all water assets in one way or another.

In the industry, we benefit from huge amounts of experience so in talking about your buildings we build a picture of what we are dealing with, by being as honest and open as you can get the most realistic estimate possible.

Begin with the end in mind

The Legionella risk assessment certainly ticks a box for compliance but if done well is a tremendous source of information regarding your water assets. Think about practical outputs, for example, how do you expect to see non-compliances reported? Do you want them separated in a way you could pass to a mechanical contractor or your onsite plumbing team?

Talking to your suppliers about Legionella control in a wider context beyond the risk assessment can pay dividends in understanding how the document could support your efforts to implement a successful control regime later on. You’ll be amazed at what you can get for free during the risk assessment process just by asking, consider;

- Do you want accurate schematics drawn in AutoCAD?

- Would it be handy if the pipe runs are overlaid on your existing building schematics?

- Would you like an electronic copy of the asset register in excel?

- Do you want the assets in an electronic logbook?

At the end of the day

All Legionella risk assessment quotes have at their core have an estimation of how long the survey is going to take and the report to produce, as a buyer you should understand and be comfortable that your supplier will do a job that is acceptable to you in the time they have quoted. Industry rates vary from £350.00 to £600.00 per day for a qualified Legionella risk assessor as a guideline.

There are many decent companies out there, and all of them should welcome sensible discussions on the big question – how long is it going to take?

Dantek is a specialist provider of Legionella control services including Legionella risk assessments.

If you have any further questions or would like to speak to one of our sales team, please call us on 01454 417920 or e-mail sales@dantek.co.uk

Keep up to date with our news on Linked in.

https://www.linkedin.com/company/dantek-environmental-services-uk-ltd

Legionella control case study at a large boarding school

Dantek have provided legionella control services to Marlborough College for a number of years, below is a case study about how we work together to ensure ACoP L8 compliance and the safety of the students and staff.

Since its establishment in 1843 by a group of Church of England clergymen at the Castle Inn at Marlborough, Marlborough College has never been frightened of change.

In its recent history, numerous academic initiatives have been fostered at the College including, Business Studies, SMP Maths, Combined Science, Pre-U examination syllabuses and the teaching of Arabic and Chinese. In 1968 Marlborough was one of the first of the traditional boys’ boarding schools to admit girls into the Sixth Form.

In 1989, the College became fully co-educational with the admission of girls into the Lower School and with the establishment of the first of the all-girl boarding houses.

Today the College caters for 936 pupils (of which just over 40% are girls) and the great majority of whom (98%) are boarders. The remaining four “Out-College” houses accommodate 13-16-year-old boys, plus a mixed Sixth Form of both girls and boys.

School size: 201-500 employees

Based at: Marlborough, Wiltshire

The support Dantek provides

As a school, Marlborough College provides care for a large group of students most of which board on site, this means that they must adhere to strict health and safety guidelines. One of these areas is the need to protect students and staff from potential Legionella infection. Dantek has worked with the school for many years ensuring they comply with all regulations thus providing a safe environment for their students to thrive in.

As part of their on-going activity, Dantek engineers monitor the water quality, carry out remedial work and run regular testing and Legionella risk assessments. The College compliance team benefit from using Dantek’s electronic logbook which saves time and helps them keep on top of the various requirements. Dantek has provided a long-standing service to the college and act as part of their team which supports the quality of environment and interaction required by the College.

What does the client say?

We caught up with Kelvin Neale, M&E and Energy Manager at Marlborough College to find out how he views working with Dantek;

How did you hear of Dantek?

I have worked at Marlborough College for 8 months so Dantek were already in place when I joined. However, I did work with Dantek through another employer. I can certainly say that Dantek are known for their sound reputation in the industry.

What are the most important elements you look for in a contractor?

The most important elements for me are timely communication and a conscientious, effective manner. Due to the nature of the work Dantek provide, I also look for clear paperwork and accurate paper trial. We do consider the price, but it is not the only factor. When it comes to compliance, we must make sure we are choosing the right supplier who has the knowledge and systems which we require.

What do you like about working with Dantek?

I am very happy with their work in general. Three things stand up for me in particular:

- All engineers are professionals and knowledgeable, DBS checked and employed directly. They will always provide a service that goes beyond their contractual requirements and nothing we ask is ever an issue.

- The level of knowledge and expertise the company holds is impressive, they clearly know their stuff. I am also very impressed with the fact that on the rare occasion when they come across something they don’t know; they will go away to research for the right solution. It really demonstrates how competent they are and allows me to trust their advice implicitly.

- The electronic logbook is helpful and saves me a lot of time. It means I always have the data I need available to me and we never miss any tests and activities we need to complete.

How do they stand out against the competition?

As mentioned before, Dantek has a strong reputation in the industry. I think the main elements that make them stand out for me are as follows:

- The concise and timely completion of every job

- The electronic logbook which allows me to stay on top of compliance requirements, documentation and paperwork

- The level of knowledge and expertise they demonstrate about water treatment and legionella control

5 key issues to consider about Legionella and care homes

Legionnaires’ disease can cause serious illness and, in some cases, even death if it is not managed correctly. It is contracted by breathing in droplets of air containing Legionella bacteria. Legionella bacteria occurs naturally and enters the water system through the mains water supply. Airborne water droplets are created by water systems such as showers, spa baths, hydrotherapy baths and hot and cold-water services such as spray taps.

While anyone could become infected there are some groups who are more susceptible, and these include the elderly and those with existing underlying health conditions. Therefore, it is so important for Care Homes to act and put in place a robust management system and practical solutions to protect anyone in their care who may be at risk from the disease.

There are no known cases of Legionnaires’ disease from the natural environment, this is because it is only in man-made water systems where the conditions are right for the bacteria to proliferate.

Earlier this year the private care provider BUPA was fined £3m for failing to prevent and control an outbreak of Legionnaires’ disease when very sadly a resident died. Click on the link below to read more: https://www.healthandsafetyatwork.com/legionnaires-disease/bupa-kenneth-ibbetson

Where to start?

Controlling legionella in nursing and residential care homes starts with a legionella risk assessment of the hot and cold-water systems to ensure a scheme is put in place to control the risk. Temperature is the usual method of control with systems operated at the required temperatures to prevent legionella bacteria from growing. Hot water must be stored at 60°c and distributed at 50°c or higher to all outlets. Thermostatic mixer valves may need to be fitted at outlets to prevent scalding. Cold water must be stored and distributed at 20°c.

Regular checks need to be carried out in accordance with the risk assessment, some of these checks can be carried out by your own trained site staff or alternatively you can choose an experienced water hygiene company to do these on your behalf. Whichever option you choose a key factor for compliance is the management of the control scheme which includes correct record keeping.

Cold water storage tanks must be visually inspected at least every 6 months and cleaned as required. The temperature of stored water must be checked to ensure it is 20°c or less. Showerheads and hoses must be cleaned and descaled quarterly. Calorifiers (hot water cylinders) need to be drained and internally cleaned and inspected annually.

It is also important to reduce the possibility of stagnating water in a system, so a risk assessment will identify dead-legs in the pipework which will need to be removed. Little used outlets which can include showers and taps must be flushed weekly or removed to prevent stagnation.

Electronic log book

Using a cloud-based log book is one of the best ways to keep on top of all the monitoring tasks which need to be performed. Dantek has developed an easy to use cloud-based system which we provide for free to all our contract customers. The system ensures all your data for legionella compliance is held in one place and can be reported on and scrutinised, so you know where any problems are and what you need to do to rectify them. For a short demo of the system please email info@dantek.co.uk.

5 key points to consider

- Do you have an up to date legionella risk assessment and control scheme in place?

- Who is the competent person to manage the risks from legionella?

- Are your water systems kept clean, with correct temperature controls and no stagnant water?

- Are you frequently checking temperatures remain in line with the ACoPL8 HSE guidance?

- Do you have accurate records in place to show external agencies?

Dantek is listed on the Legionella Control Association directory of companies who specialise in the prevention and control of legionella bacteria. Do get in touch if you would like to find out more about our legionella prevention and control plans.

Employee profile: David Edwards Legionella Risk Assessor

When did you join Dantek?

I have been working at Dantek for 10 years, I started doing monitoring, tank cleaning, remedial works and cooling tower disinfections. I then progressed into Legionella risk assessing about 5 years ago. Before joining Dantek, I was at another company cleaning and disinfecting cooling towers and carrying out remedial works on cooling towers as well as tank cleaning and disinfection work. So, by the time I came here as a lead engineer I already had a wealth of experience in the industry.

Becoming a Legionella risk assessor?

Most of my training has been on the job, I started at bottom and have worked my way up by building on experience. I am a qualified plumber so that really helped with my career as it meant I have a solid understanding of how buildings are plumbed and how water systems work. Particularly now as a risk assessor I can easily identifying risk as I know what looking at. I have done every single aspect of water hygiene so can draw on my knowledge when risk assessing a building.

I have spent years of my life stripping cooling towers and working in cooling towers so risk assessing them came very naturally as I have a thorough understanding of how they work.

Of course, I do have formal qualifications in legionella risk assessing but I firmly believe the best way to learn is from practical experience rather than academic study alone.

Where do you start when carrying out a legionella risk assessment?

I tend to start in main plant areas and work my way from there, generally they are the biggest areas of risk. Start with tanks and calorifiers and then move to identifying blinds ends, dead legs and return loops. I will also request to see any records or previous risk assessment on the building which can be a helpful starting point, although of course it needs to all be updated and schematics drawn to ensure they are accurate, and everything is up to date.

What challenges do you come across?

Cooling towers are challenging, as the legionella risk is potentially so much higher.

Buildings can also be deceptive as a straight forward looking 2 storey building could house any number of systems for example; there could be a lab or have reverse osmosis system, so you need to wait until you discover what is inside.

What work are you most proud of?

Herm Island is definitely my proudest achievement as I have risk assesses every single property on the Island. All the water is fed from a bore hole, so it has its complications. I go there every 2 years to update the risk assessments and am so impressed as they have carried out all the recommendations I made in my initial risk assessment. Given they cannot just pop to B&Q as they are an island, they must ship every single part and material in order to do all the remedials, but they have done it all and taken everything on board, which I am afraid to say not everyone does so thoroughly.

I also enjoy going into places and finding tank, calorifiers and even taps that people are unaware they even have. I am often told there are “no tanks in our building” only to find there were hidden behind a panel or roof space. It is really satisfying to know you have done a thorough job and being naturally inquisitive has helped me to make sure every tank, calorifer and tap are assessed.

What are the best features of our risk assessment reports?

I think customers find the asset register and photos useful as it clearly sets out exactly what you have on site. The risk score is also highly valued by customers because it shows what your risk is now and what your projected risk could potentially be if you put in place the control scheme suggested and carry out the remedial work.

We also explain why the risk score has been given with an in-depth explanation for customers. I think this is good because it helps to prioritise where to take action first to make the most impact to reduce the risk on their sites.

What do you enjoy about your job?

I love the freedom of the job and being out and about visiting different places. I like the trust the responsibility of the job and the satisfaction of knowing the work I do can make a difference by helping to ensure no one suffers with Legionnaires’ disease.

What do you like doing for fun?

I really enjoy sea fishing and try to do as much as I can. I support Cardiff City both at home and away. I am currently planning a holiday to Vietnam for next year which will be a great experience and hopefully I will be able to fit in a bit of fishing while I am there.

How much should a Legionella risk assessment cost?

Your concerned about compliance and you want a good company, but still, budgets are tight, you need the best value, so what do you need to tell contractors to get a fair price? Or get quotes you could compare? And how do these people work it out anyway? I will attempt to throw some light on the occasionally opaque world of Legionella or water risk assessment pricing.

As a start point I have assumed that you are only going to be dealing with reputable contractors who are specialists in the industry, generally members of the Legionella control association, possibly UKAS accredited, who can prove they are competent and have a solid track record. There have been operators in the marketplace who will ‘buy’ risk assessment contracts with the intention of raking the money back on follow-on works and contracts, this is a clear conflict of interest, and I advise avoiding it.

A Legionella risk assessment is a form of consultancy, which means it is, for the most part, a labour only service. This means the big question is – how long is it going to take? Once we figure this out, multiply the time by a day rate and bingo! A price.

Top tip; Ask what the standard day rate is for a surveyor, but be careful, some include administration time some don’t.

Estimating how long a survey will take is a fine art, but there are some variables to consider:

Geography

Where is the site? Or where are the sites? Travel time is working time, and you pay for it. Ideally, you’ll use someone local if you have a big single site or cluster of buildings, but sometimes this isn’t practical. If you have many disparate sites, you can get some great economies on a round robin or road trip type basis. Also, these are fun for the surveyors. Years ago, I risk assessed every driving test centre in Scotland on a road trip basis and had a great time.

Once you understand the logistics of getting the surveyor to and from the site, how long will they be there? The two big factors in this debate are; what water services have you got? And how hard will they look? The second point can be contentious, so I’ll deal with what you’ve got first.

Water Assets and system complexity

I have seen many different approaches to convey what is on site, varying from line item asset registers, copies of the previous risk assessments to lists of the gross internal areas of properties. The surveyor’s point of view generally stems from, how difficult is this system going to be for me to understand and how many assets do I have to survey? For example, a large modern office block could seem like a big beast but in reality, may have plant room in the basement, a single wet riser by the lift shaft, toilets and kitchenettes on each floor plus a couple of cleaners cupboards, simple. In contrast, a stately home converted to halls of residence can contain multiple systems and a dog’s breakfast of assets and pipework that would reduce the finest to tears.

Top tip: Give what information you have, including building use, number of stories, and location

The industry refers to all hot and cold-water systems for toilets, sinks, showers etc. as domestic systems. These are almost universally included in risk assessments, but what about cooling towers, industrial uses of water, humidifiers, water features, medical equipment? The survey should cover all water assets one way or another.

In the industry, we benefit from huge amounts of experience so in talking about your buildings we build a picture of what we are dealing with, by being as honest and open as you can you will get the most realistic estimate possible.

The depth of the survey

If you have been on the forums this is a hot potato; the fastidious independent contractors shout down the ‘stack’em high sell it cheap’ brigade for being cowboys and the quick ‘all done on an iPad survey’ crew retort about over-egging the pie. The truth is the risk assessment must be suitable and sufficient, just as the lower the risk, the less you have to do, the converse is also true. There is a place for the iAuditor type surveys on lower risk properties, retail outlets, provincial train stations and minor highways depots etc.

Conversely, if you’re looking after NHS estates, your burden is much greater. The best advice I can give is to view example documents on properties similar to yours, talk to the contractor and understand what they intend to return. You need to feel comfortable the contractor has your best interests front and centre, and they are not ‘flogging you what they’ve got’.

Begin with the end in mind

The Legionella risk assessment certainly ticks a box for compliance but if done well is a tremendous source of information regarding your water assets. Think about practical outputs, for example, how do you expect to see non-compliances reported? Do you want them separated in a way you could pass to a mechanical contractor or your onsite plumbing team?

Talking to your suppliers about Legionella control in a wider context beyond the risk assessment can pay dividends in understanding how the document could support your efforts to implement a successful control regime later on. You’ll be amazed what you can get for free during the risk assessment process just by asking, consider;

- Do you want accurate schematics drawn in AutoCAD?

- Would it be handy if the pipe runs are overlaid on your existing building schematics?

- Would you like an electronic copy of the asset register in excel?

- Do you want the assets in an electronic logbook as part of the deal?

A word about water samples

There is no hard or prescribed requirement to take microbiological samples during the risk assessment process, in our company we don’t take them as a matter of course but others do. I could write another thousand words on the pros and cons of sampling, but ultimately, to compare quotes you need to understand if they have been included for and if so how many. The current market rate for a Legionella test at a UKAS accredited laboratory is about thirty pounds so cost can be significant if a meaningful number of samples are taken.

At the end of the day

All risk assessment quotes have at their core an estimation of how long the survey is going to take and the report to produce, as a buyer you should understand and be comfortable that your supplier will do a job that is acceptable to you in the time they have quoted. At the bulk end of the market, if you are paying one hundred pounds or less for a risk assessment, your contractor is expecting to do four or more sites per day and is not expecting to find very much. Industry rates vary from three hundred to six hundred pounds per day for a qualified Legionella risk assessor as a guideline.

There are many decent companies out there all of them should welcome sensible discussions on the big question – how long is it going to take?

Dantek are a specialist provider of Legionella control services including Legionella risk assessments.

Sign up for our mailing list to keep up to date with latest information and comments on legionella control.