Cooling tower water treatment – FAQ’s

What do I need to do if I am responsible for a cooling tower?

The first step is to carry out a Legionella Risk Assessment, it will need to be conducted by a competent water treatment professional with expertise in cooling towers. The risk assessment will form the basis of control measures put in place to reduce the risk of legionnaires’ disease.

You will also need to register the Cooling Tower with your local authority.

(The Notification of Cooling Towers and Evaporative Condensers Regulations 1992). These Regulations require employers to inform their local authority, in writing, if they operate a cooling tower or evaporative condenser and include the location of the tower to be used in case of an outbreak of Legionnaires’ disease. It is also a requirement for employers to notify when cooling towers are no longer in use. Notification forms are available from your local environmental health department.

https://www.gov.uk/cooling-tower-notification

What are cooling towers used for?

Cooling towers provide cooling for a wide range of industrial processes and air conditioning.

Cooling tower means a device whose main purpose is to cool water by direct contact between the water it holds and a stream of air.

Evaporative condenser means a device whose main purpose is to cool a fluid by passing the fluid through a heat exchanger which is itself cooled by contact with water passing through a stream of air.

Essentially, they are both arranged so that the air moves against the direction of the water.

The process of using evaporative cooling of water is widely used to deplete heat from air conditioning, refrigeration and industrial process systems. There are a range of evaporative cooling systems that use the evaporation of water to achieve this cooling effect and these include cooling towers and evaporative condensers. Open-circuit cooling towers are the most common and range in size from small packaged towers used in air conditioning and light industrial sites, up to large towers, including hyperbolic towers for heavy industrial uses.

Water boils at 100℃ and freezes at 0℃ and these changes of state from liquid to steam require an additional input of energy known as the latent heat of vaporisation.

The energy required to change 1 gram of water into steam is the highest of any known liquid which makes it particularly good as a cooling medium. As the water evaporates it takes a large amount of energy with it which cools the remaining liquid considerably.

Why cooling tower water treatment is needed?

The water used in cooling towers needs to be treated because impurities in the water cause the following problems all of which require actions for the system to run efficiently:

- Scale

- Corrosion

- Suspended solids

- Microbiological growth

It is important to have in place an effective water treatment programme to prevent the growth of legionella in the cooling water. A cooling tower water treatment programme should be capable of controlling not only legionella and other microbial activity but also corrosion, scale formation and fouling to maintain the system’s cleanliness. Appropriate water treatment may involve a range of chemical and physical techniques to control corrosion, scaling and fouling potential of the cooling water and to control microbial growth. Any water treatment regime must be monitored regularly to ensure they remain effective. The exact techniques that are required may vary significantly with different water supplies, the design of the cooling system and local operating conditions so it is important to engage a water treatment consultant to ensure the correct selection of control measures for your site.

How do you prevent legionnaires disease in cooling towers?

The first action is to identify and assess the sources of risk and appoint an individual who is managerially responsible for the system. This person must be trained and competent and must also have the authority and budget to act when necessary. The next step is to prepare a written scheme to include temperature monitoring, chemical treatment and any remedial works required to ensure compliance with current guidance. Once a scheme has been prepared it needs to be implemented, managed and monitored. Information must be held in a logbook so records are accessible and can be used to check the scheme remains effective. The records must be regularly reviewed, and any changes made to ensure effectiveness. Records must be kept for 5 years.

It is a legal duty to control the risk of exposure to legionella bacteria. As legionella bacteria are more likely to grow and proliferate in a cooling system fouled with sludge, scale and other deposits, maintaining system cleanliness and the water in it is an essential part of the control regime. The cleaning and disinfection frequency must be determined by a risk assessment and this should be based on inspection and the history of the water treatment control of microbial activity, scaling tendencies and other factors that may result in fouling of the system. In relatively clean environments with effective control measures, it may be acceptable to extend the period between cleaning operations, provided you can demonstrate that system cleanliness is maintained.

Water quality monitoring

The composition of the make-up and cooling water must be routinely monitored to ensure the continued effectiveness of the treatment programme. The frequency and extent will depend on the operating characteristics of the system. There are some checks which must be carried out weekly for example TDS and pH, while others are much less frequent for example legionella testing which is typically carried out quarterly.

Routine checks on cooling towers:

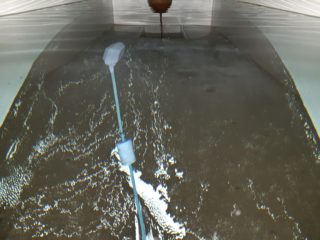

There are various checks which must be performed daily; these include a visual check of the cooling tower, check on the internal condition, dosage equipment and chemical drum levels check.

Every week the oxidising biocide levels, conductivity (TDS), pH, microbiological activity, pumps and softener must be checked and records updated in the logbook.

Why is scale a problem is cooling towers?

Scale is one of the four main issues found in cooling towers below are 5 of the key implications of scale:

- Scale reduces heat transfer

- Scale promotes corrosion

- Scale promotes microbial growth for example legionella bacteria

- Scale absorbs chemical treatments

- Scale can obstruct pipework causing inefficiency and increased energy costs

Scale is the localised build-up of normally water-soluble inorganic hardness salts. Its formation is influenced by the concentration of calcium salts, pH, surface and bulk water temperatures and the concentration of the total dissolved solids (TDS). As an evaporative cooling system operates, the concentration of these various dissolved solids increases and the pH of the water tends to rise, which results in the scaling potential of the water increasing.

Scale formation results in loss of heat transfer, reduced flow rates and loss of efficiency and contributes to deposition. Legionella can be associated with such deposits. The scale protects the bacteria and so reduces the effectiveness of any biocidal treatment.

One or more of the following techniques generally control scale formation:

- removing the hardness from the make-up water by pre-treatment, e.g. water softening

- adding specific scale inhibitors that extend the solubility of the hardness salts and so prevent precipitation

- acid dosing to lower the pH and alkalinity and reduce the scaling potential

- limiting the system concentration factor to a range within which the hardness salts can remain soluble

What is TDS in a cooling tower?

Conductivity or Total dissolved solids (TDS) the quantity of solids dissolved in the water, measured in mg/l. These solids will typically include calcium and magnesium (sodium in softened water), bicarbonate, chloride, sulphate and traces of other materials. TDS indicates general water quality.

What are dipslides used for in cooling towers?

Dipslides are used to measure the level of bacteria. They are incubated at 30°C for 48 hours and bacteria will show as red spots. A comparison chart is used to assess the level of bacteria.

For further information about water treatment service contracts for cooling towers contact us to talk through how we can help keep your cooling tower running efficiently and compliant with the latest HSE guidance for Legionella control.